Two reasons why ceramic tools can be used for “high-speed cutting” – NTK Cutting Tools Lab

If you hear “ceramic tool”, does an image of it “breaking” come to mind? Like if you drop a tea cup, it’s breaking, right? In this article, we will discuss two reasons why ceramic tools can realize significant “productivity improvement” at the manufacturing site.

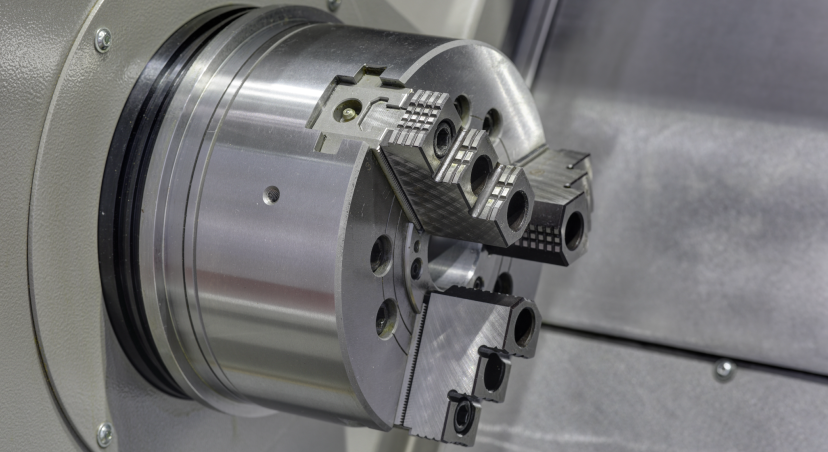

Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕 – NTK Cutting Tools Lab

A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕 – NTK Cutting Tools Lab

A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

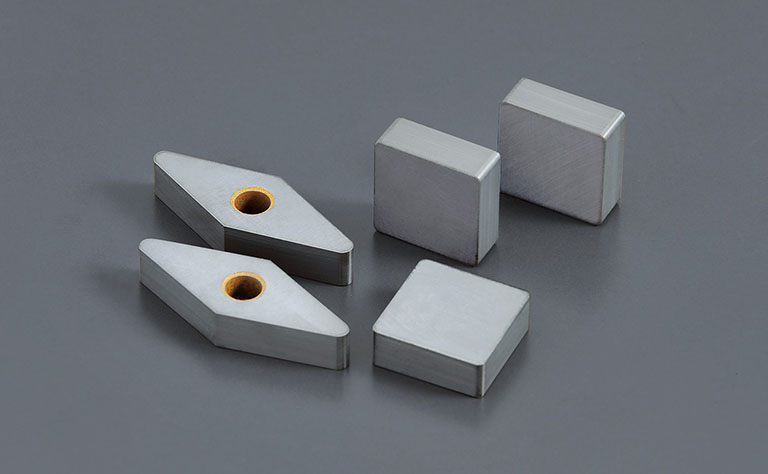

Ceramic Cutting Tools - an overview

NTK Cutting tools]High speed milling with ceramics insert ''JR''

B23/B30 - High-speed finishing of gray cast iron|NTK CUTTING TOOLS Co., Ltd.

A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

Ceramic savvy Cutting Tool Engineering

Ceramic Cutting Tools - an overview

Advanced Ceramics Lab – NTK Cutting Tools Lab

The difference between a Swiss type CNC automatic lathe and a traditional CNC lathe and the cutting tools used – NTK Cutting Tools Lab

Two reasons why ceramic tools can be used for “high-speed cutting” – NTK Cutting Tools Lab

Performance of Al2O3/TiC mixed ceramic inserts coated with TiAlSiN, WC/C and DLC thin solid films during hard turning of AISI 52100 steel - ScienceDirect