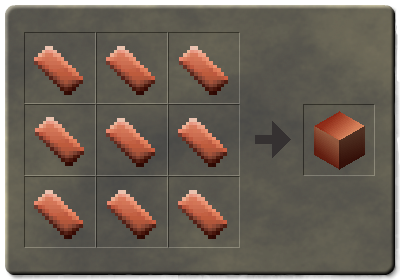

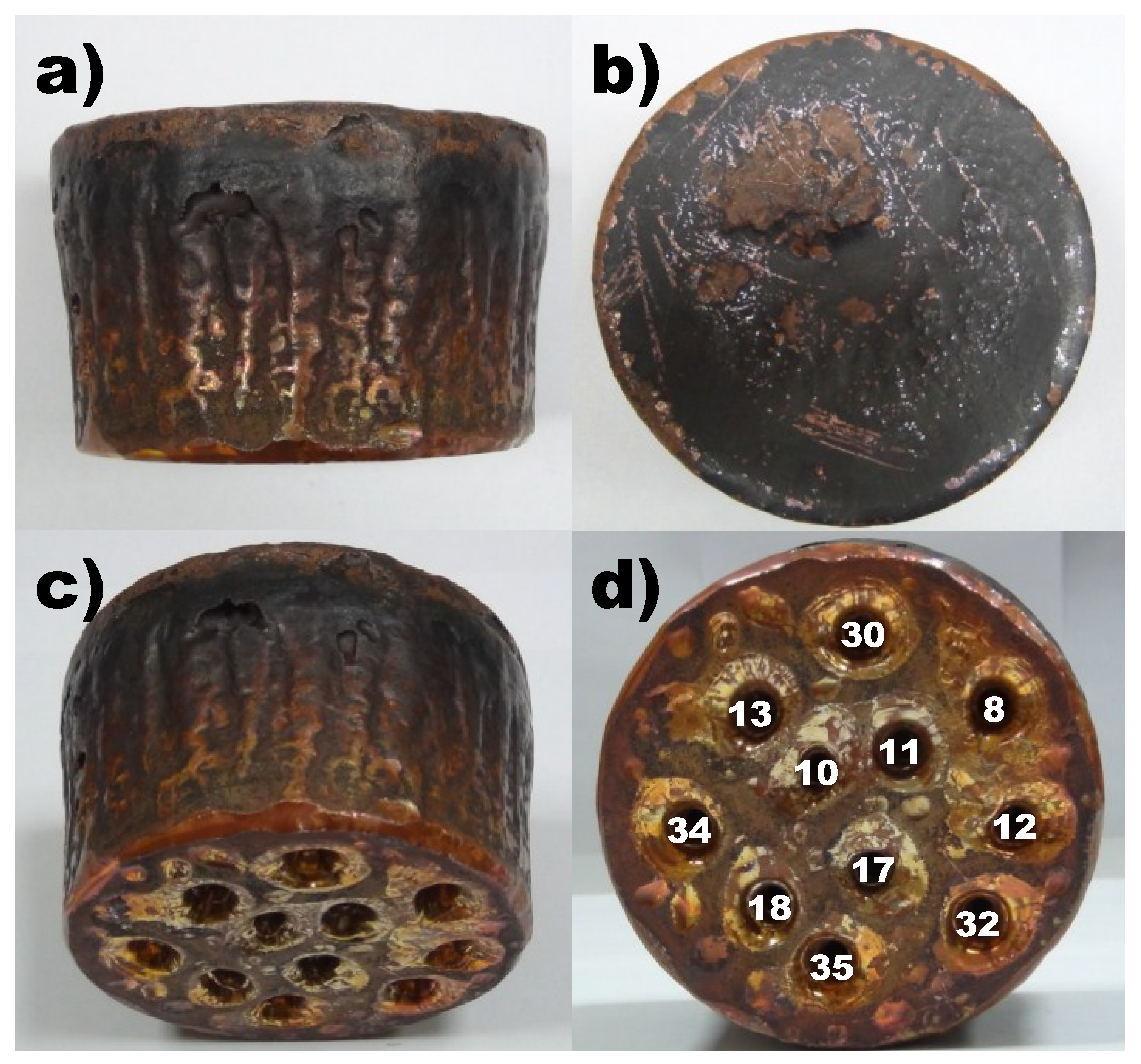

a shows a copper ingot prepared by melting grade a copper plate in

Download scientific diagram | a shows a copper ingot prepared by melting grade a copper plate in a 50Kg vacuum melting furnace, with a diameter of 180mm and a weight of 50Kg. Samples were taken along the cross section of the copper ingot and soaked in 30% nitric acid solution for 12 min. The grain morphology can be seen in figure 1-b: the copper grains in the as-cast state are mostly large flake and equiaxed grains, and the slower cooling rate made the grain size and shape more uniform, which was more conducive to the refinement and homogenization of grains during the plastic deformation of hammer forging. from publication: Structure of copper shaped charge liner evolution law based on die forging process | Numerous studies have addressed the effect of grain size of materials on the overall penetrating performance of warheads. However, the use of the forging process to illustrate the grain heat-treatment refining technology has not been reported. In this experiment, the grain | Copper, Fees and Charges and Jurisprudence | ResearchGate, the professional network for scientists.

copper buyers Indiana Garden City Iron & Metal

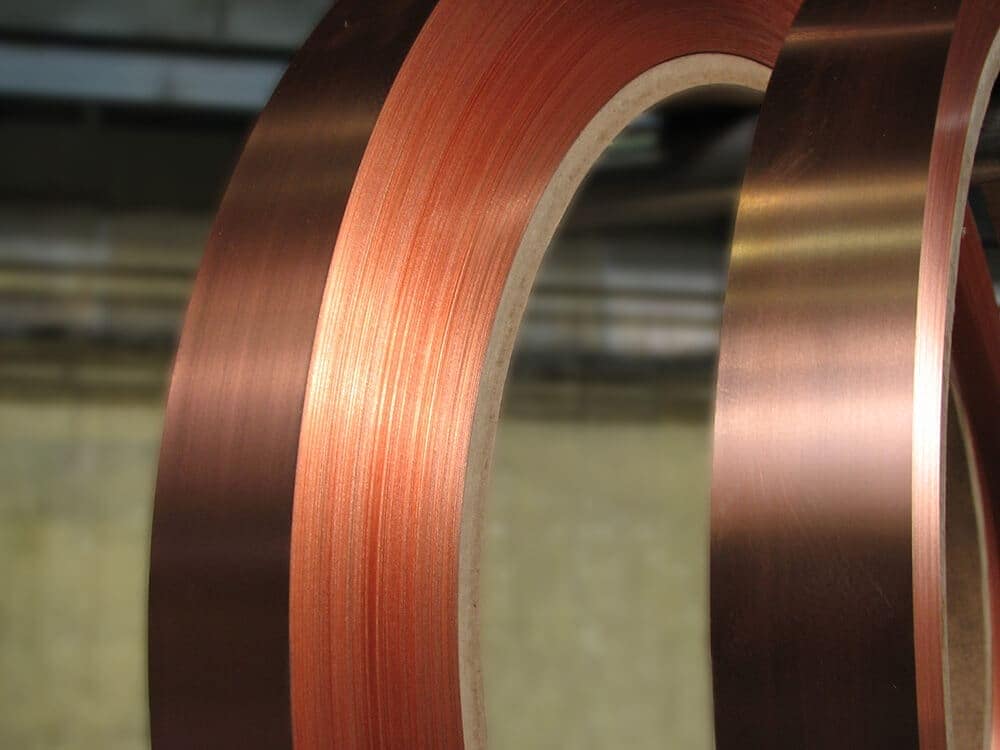

Copper Strips and Copper Sheets Walcownia Metali Nieżelaznych

Copper Mining and Processing: Processing Copper Ores

The Cu-Sn equilibrium diagram.

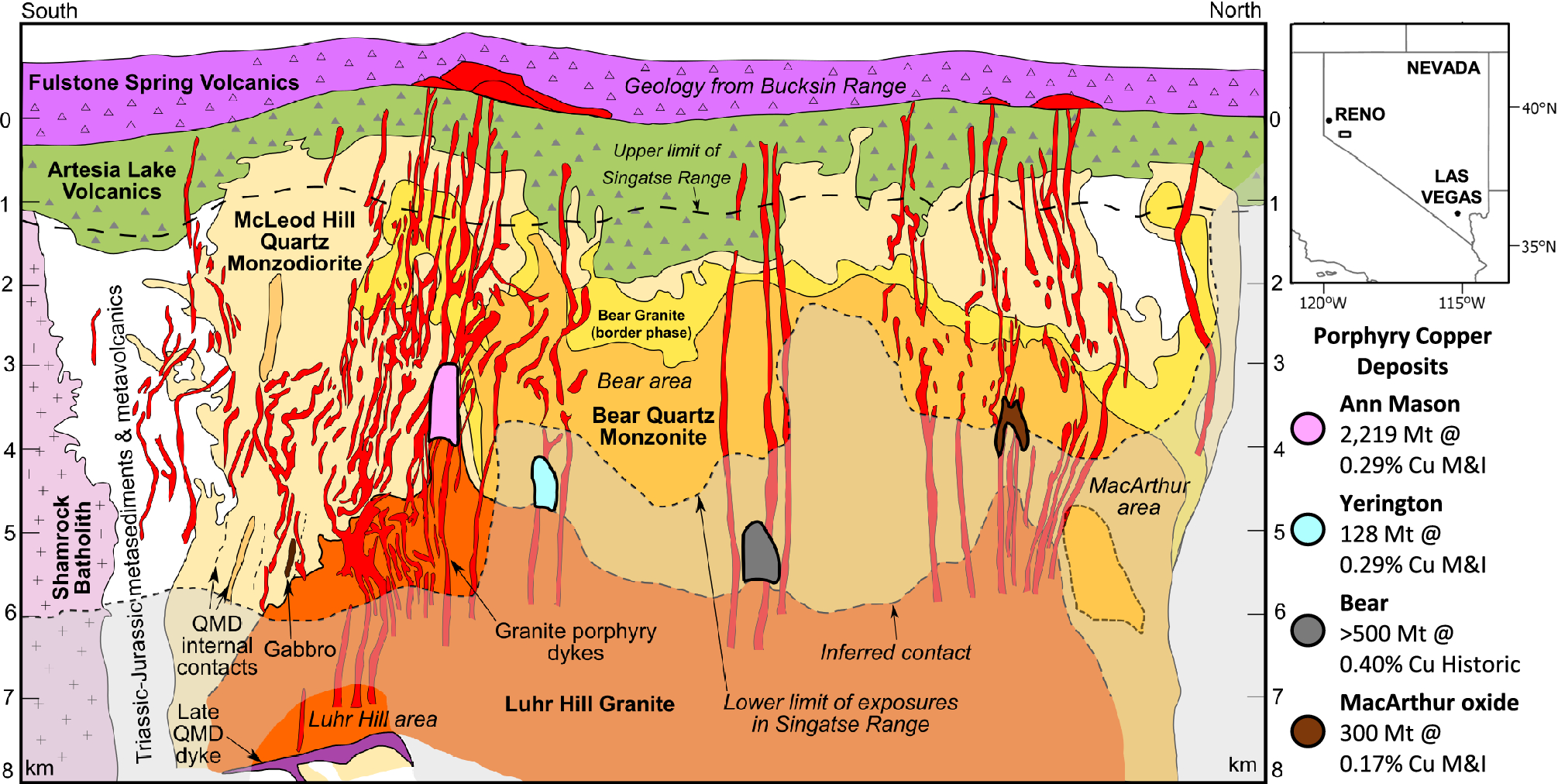

A rapid change in magma plumbing taps porphyry copper deposit

Copper Sheets: Types of Sheets, Types of Alloys, Applications and

Types of Aluminum: Types, Uses, Features and Benefits

PDF) Structure of copper shaped charge liner evolution law based on die forging process

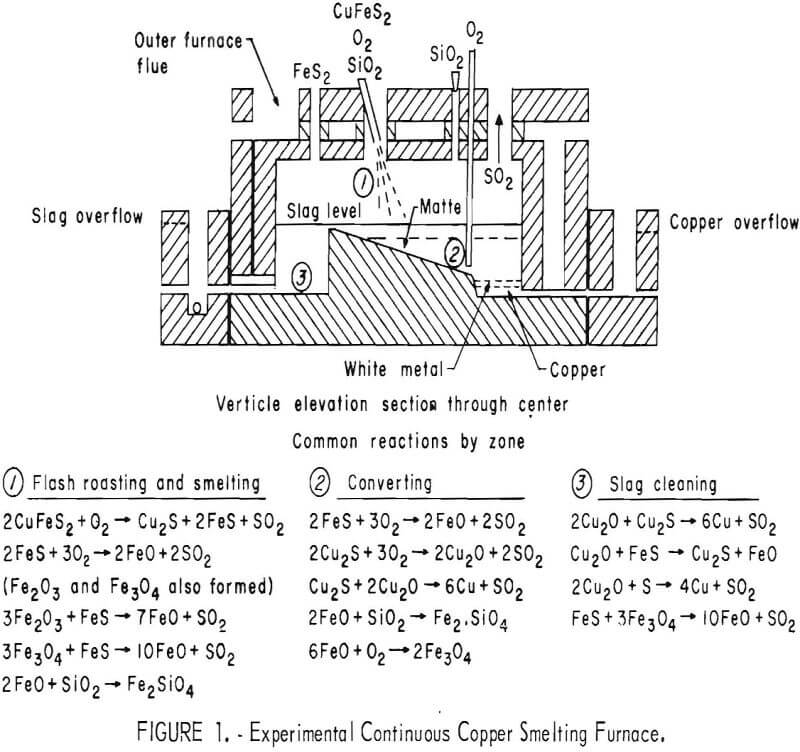

Copper Smelting

Metals, Free Full-Text

How to Clean and Care for Copper Cookware