How To Make a Silicone Mold Using Mold Star 15 - AMT Composites

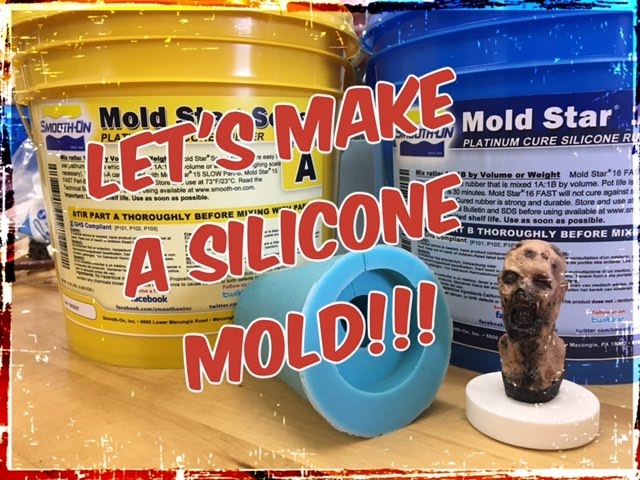

LET'S MAKE A SILICONE MOLD!!! Using Mold Star 16 from Smooth On!

On the behavior of sub‐micrometer polystyrene particles subjected to AC insulator‐based dielectrophoresis - Bu - ELECTROPHORESIS - Wiley Online Library

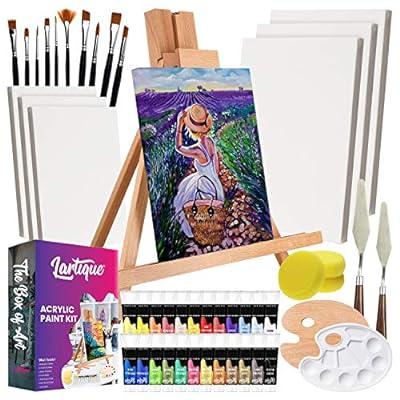

Mold Star 15 Slow - 1A:1B Mix by Volume Platinum Silicone Rubber - Pint Unit

Pharmaceutics, Free Full-Text

PLAS 4180 / PLAS 5180 Plastic Part Design: Other Molding Processes, PDF, Cross Link

Binder jet 3D printing—Process parameters, materials, properties, modeling, and challenges - ScienceDirect

FDM 3D Printing (Fused Deposition Modeling) Services

Unit Size, Net Weight, Pint Kit, 2 lb, Gallon Kit, 18 lb, Five Gallon Kit, 90 lb, Mold Star rubbers are easy to use platinum silicones which are mixed

Mold Star 15 Slow

Mold Star 15, 16 & 30 Available in the US and Canada - Reynolds Advanced Materials

Smooth-On Mold Star 16 Fast

PDMS Curing Inhibition on 3D-Printed Molds: Why? Also, How to Avoid It?

The Deterioration Mechanism of Silicone Molds in Polyurethane Vacuum Casting

AMT Composites