Standard Staple Yarn Spinning Procedures - Textile School

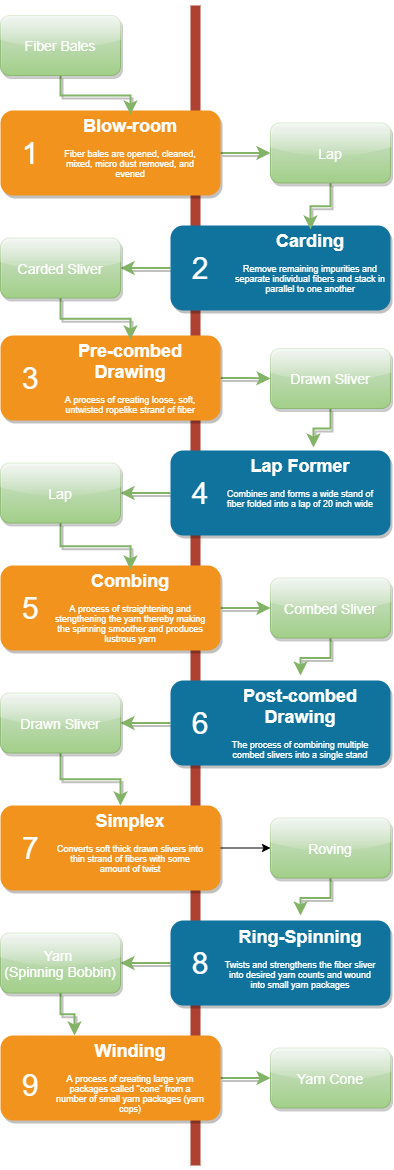

Yarn making from staple fibers involves picking (opening, sorting, cleaning, blending), carding and combing (separating and aligning), drawing (re-blending), drafting (drawing into a long strand) and spinning (further drawing and twisting). Silk and synthetic filaments are produced by a less extensive procedure. Current high-production yarn-making operations are performed on integrated machines that perform this entire sequence as one combined operation.

a knowledge-base repository of textile articles

Yarn making from staple fibers involves picking (opening, sorting, cleaning, blending), carding and combing (separating and aligning), drawing (re-blending), drafting (drawing into a long strand) and spinning (further drawing and twisting). Silk and synthetic filaments are produced by a less extensive procedure. Current high-production yarn-making operations are performed on integrated machines that perform this entire sequence as one combined operation.

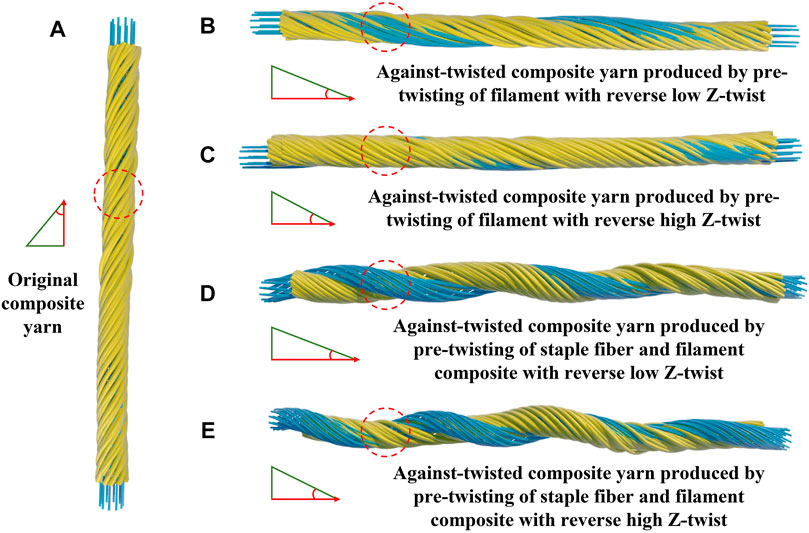

Frontiers A spinning method for low-torsion composite yarn with basalt fibers and staple cotton fibers

Standard Staple Yarn Spinning Procedures - Textile School

Textile Spinning Process II Making of Staple yarn and Filament yarn

Textile Industry, Definition, History & Processes - Lesson

Staple Length - an overview

Yarn Processing - A Report on Spinning Process Prepared By Engr. Saad Ahmed Salman Table of Contents - Studocu

Denim Spinning Manufacturing Methods and Technologies - Textile School

Textile - Spun, Knitted, Weaving

Textile Industry Process - Video & Lesson Transcript

Melt Spinning - an overview