385CC UV Additive Powder – Fiberglass Source

Suggested 7cc of UV Powder per gallon of resin, adding more can result in faster cure but will result in a greenish-yellow final cured resin color,

Suggested 7cc of UV Powder per gallon of resin, adding more can result in faster cure but will result in a greenish-yellow final cured resin color. Thick laminates over 1/4" thick, pigment or logo laminates that may disrupt UV rays from fully penetrating the laminate may result in uncured areas. We suggest doing your own sample testing.The UV curing process requires a light source which directs UV or visible light onto the formulated product. Photoinitiators absorb the UV energy from the light source, setting in motion a chemical reaction that quickly, in fractions of a second, converts the liquid formulation into a solid, cured film.Methyl ethyl ketone peroxide also known as MEKP, catalyst or hardener, is a chemical that is added to polyester and vinyl resins to initiate a cured product. When MEKP is mixed with the resin, the resulting chemical reaction causes heat to build up and cure or harden the polyester resin. MEKP is required with all polyester resins, gel coats and vinyl ester resin.

Suggested 7cc of UV Powder per gallon of resin, adding more can result in faster cure but will result in a greenish-yellow final cured resin color. Thick laminates over 1/4 thick, pigment or logo laminates that may disrupt UV rays from fully penetrating the laminate may result in uncured areas. We suggest doing your own sample testing.The UV curing process requires a light source which directs UV or visible light onto the formulated product. Photoinitiators absorb the UV energy from the light source, setting in motion a chemical reaction that quickly, in fractions of a second, converts the liquid formulation into a solid, cured film.

Methyl ethyl ketone peroxide also known as MEKP, catalyst or hardener, is a chemical that is added to polyester and vinyl resins to initiate a cured product. When MEKP is mixed with the resin, the resulting chemical reaction causes heat to build up and cure or harden the polyester resin. MEKP is required with all polyester resins, gel coats and vinyl ester resin.

Suggested 7cc of UV Powder per gallon of resin, adding more can result in faster cure but will result in a greenish-yellow final cured resin color. Thick laminates over 1/4 thick, pigment or logo laminates that may disrupt UV rays from fully penetrating the laminate may result in uncured areas. We suggest doing your own sample testing.The UV curing process requires a light source which directs UV or visible light onto the formulated product. Photoinitiators absorb the UV energy from the light source, setting in motion a chemical reaction that quickly, in fractions of a second, converts the liquid formulation into a solid, cured film. Methyl ethyl ketone peroxide also known as MEKP, catalyst or hardener, is a chemical that is added to polyester and vinyl resins to initiate a cured product. When MEKP is mixed with the resin, the resulting chemical reaction causes heat to build up and cure or harden the polyester resin. MEKP is required with all polyester resins, gel coats and vinyl ester resin.

Fiberglass composites materials supplier. Surfboard shaping tools and supplies. Wholesale pricing to the public.

Milled Fiberglass powder

Vinyl ester resin used in spray-up and hand lay-up applications. It is specificallyformulated for the boat, pool, spa manufacturing industries as well

Vinyl Ester Resin

Polyester Fiberglass Resin – Fiberglass Source

Fiberglass Source Surfboard Building Supplies

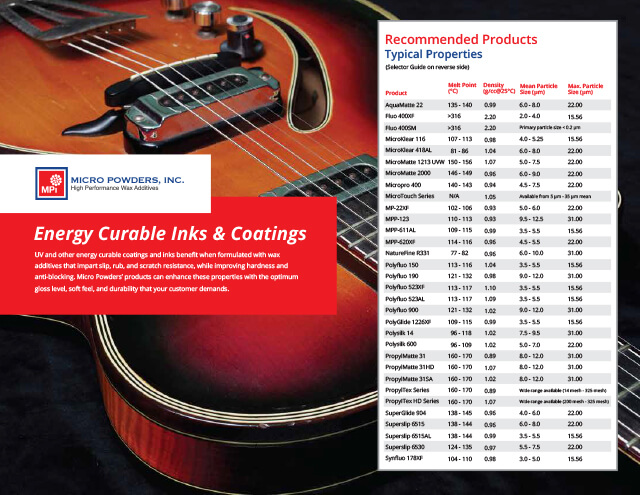

Micro Powders Inc. - Product Finder - Energy Curable Coatings

11oz-Miracle Gloss M0811V2 Mold Release #8, The industry's first and still most widely used mold release wax.Wax of choice when maximum release power

Miracle Gloss Mold Release #8

Fiberglass Source Surfboard Building Supplies

Contains a blend of synthetic waxes and is one of FK’s premium mold release waxes.Proper application of this wax will result in a film that has high

1000P Hi-Low Paste Wax

Collections – Fiberglass Source