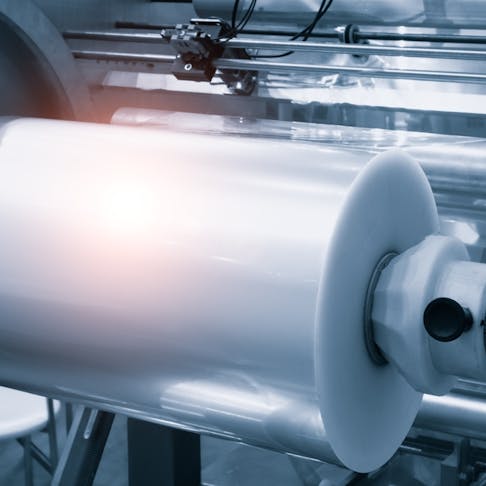

Colored Resin Addition Process In Molded Plastics, Part 2

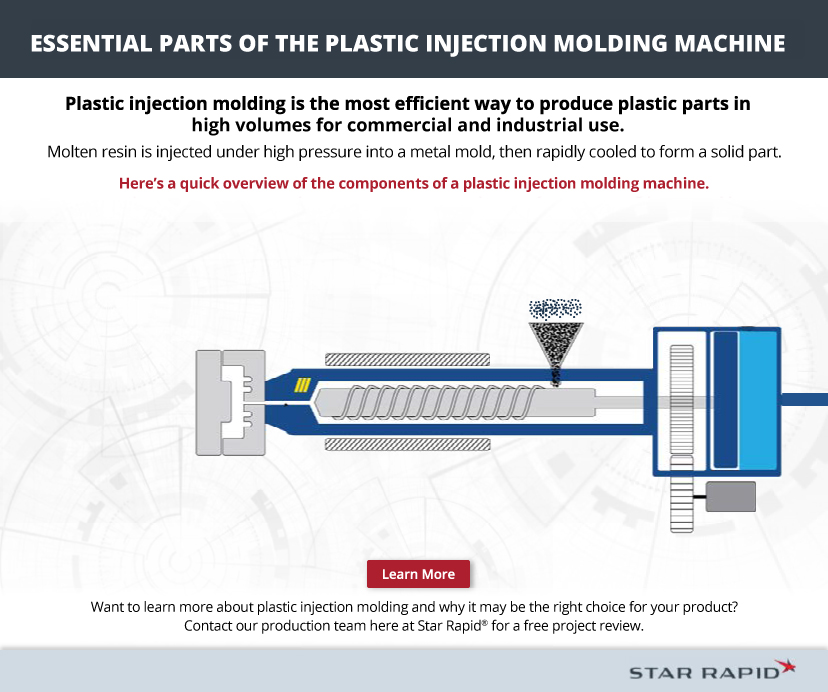

For many applications, color additives in plastic injection molding are vital factors. Here are some basics on color matching and impact on characteristics.

True Translucent is a translucent 2 part liquid polyurethane product that cures out to a translucent semi rigid plastic feel. Mix ratio is 1:1 parts

2 Part Polyurethane Casting Resin - Easy to Tint and Pigment - 3 Minute Gel time - ~15 Minute demold time - Semi Rigid Plastic Feel - 70 Shore D

Guide to Design & the LSR Injection Molding Process

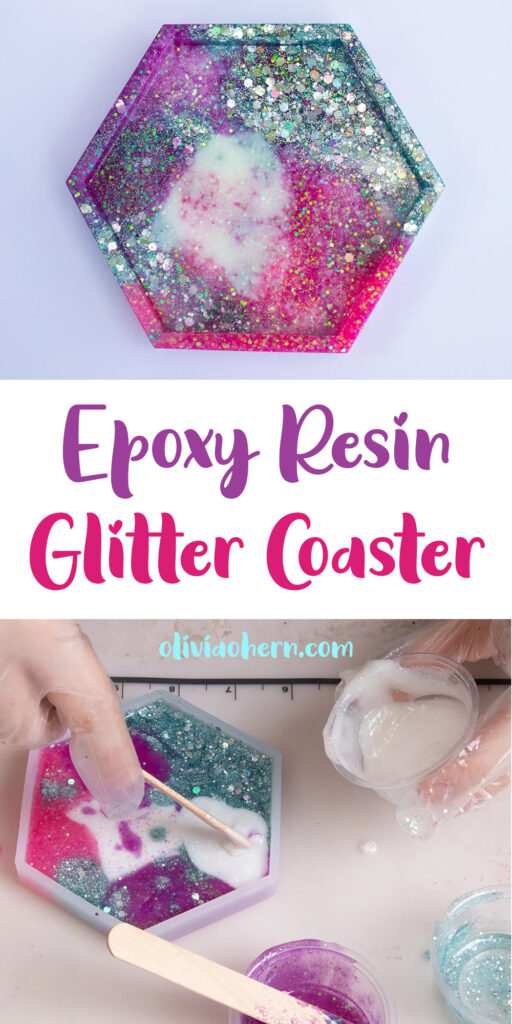

The Best Resin Crafting Projects to Try in 2024 - Resin Obsession

Woodworking 101 Guide: Everything You Need to Know about Epoxy

How to Estimate Injection Molding Cost?

The Role of Colored Resins in the Molding Process

True Translucent is a translucent 2 part liquid polyurethane product that cures out to a translucent semi rigid plastic feel. Mix ratio is 1:1 parts

2 Part Polyurethane Casting Resin - Easy to Tint and Pigment - 3 Minute Gel time - ~15 Minute demold time - Semi Rigid Plastic Feel - 70 Shore D

Plastic Injection Molding 101: From Design to Production

Plastic Injection Molding Services

Plastic: Definition, Types, Properties, Applications, Advantages

PMMA ACRYLIC INJECTION MOLDING PROBLEMS AND SOLUTIONS - Plastic

Clear and Transparent Injection Molding Tips

COMPLETE STARTER KIT - Our platinum-cured silicone supplies for mold making are perfect and easy to use. Comes with 8 colors liquid silicone rubber

Silicone Mold Making Kit - .5 Gallon Kit Translucent Liquid Silicone Rubber 15A with Silicone Pigment, Bricks - Fast Cured 1:1 Ratio Silicone Casting

Injection molding: The manufacturing & design guide