Processing and Properties of Plastic Lumber

Plastic residue can be processed into composites using wood flour, mineral fillers, plant or synthetic fibers to obtain plastic lumber, a substitute material for natural wood. The composition and processing conditions are largely responsible for the final characteristics of the plastic lumber. Factors such as density, particle size and moisture content in the material to be processed require extruders with specific technical characteristics, in order to reduce the residence time of the plastic inside the equipment, maintain a constant feed rate and ensure good degassing and homogenization of the components. The composites can be manufactured using single-screw, co- or counter-rotating conical or parallel twin-screw extruders. Plastic lumber exhibits different physical and mechanical properties from natural wood, including lower stiffness (elastic modulus) and superior weathering resistance.

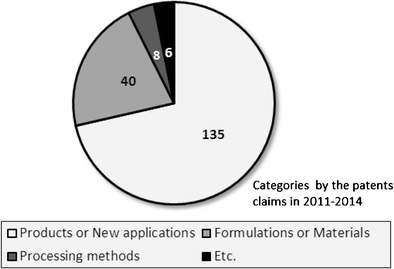

Wood–Plastic Composite Technology

PDF) Long-term creep of commercially produced plastic lumber

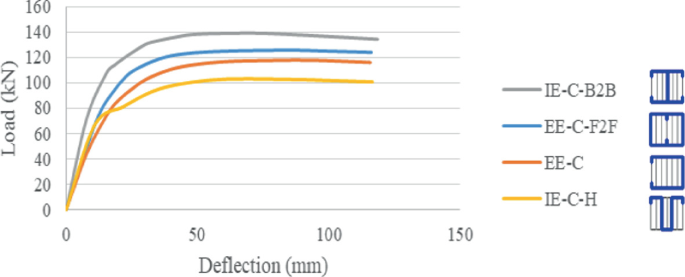

Performance Analysis of CFS Encased Recycled Plastic Laminate Beam

Potential, Challenges, and Application for Wood–Plastic Composite Fabricated with Several Additives

PDF] Processing and Properties of Plastic Lumber

Performance Analysis of CFS Encased Recycled Plastic Laminate Beam

PDF) Polywood (ppt) Abdallah EL-Gharbawy

Nerdes UFRJ Rio de Janeiro RJ

Recycled Polypropylene-Coffee Husk and Coir Coconut Biocomposites: Morphological, Mechanical, Thermal and Environmental Studies

Long-term engineering properties of recycled plastic lumber used in pier construction - ScienceDirect

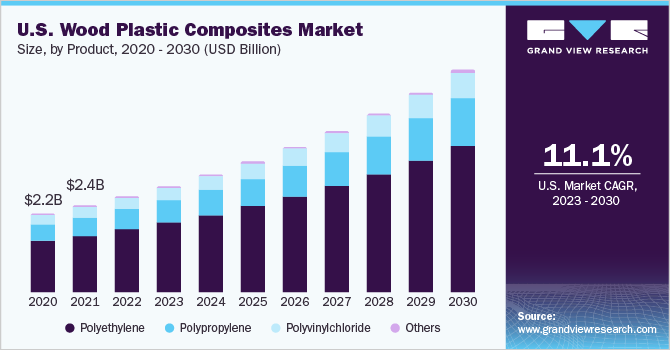

Wood Plastic Composites Market Size & Share Report, 2030

WO2011011590A1 - Cross-linked wood plastic composite - Google Patents

5 Comparison of Some Plastic/Composite Mechanical Properties

PDF] Processing and Properties of Plastic Lumber

The Most Common Plastic Injection Molding Materials

:max_bytes(150000):strip_icc()/parents-relaxing-outdoor-with-children-playing-on-patio-176643281-5a95d6afc0647100376385f2.jpg)

:max_bytes(150000):strip_icc()/SPR-HOME-10-best-wood-fillers-5089771-01-59f9d81d4adf40b2a85a2f4d45986b23.jpg)

/cloudfront-eu-central-1.images.arcpublishing.com/diarioas/RME3NYCALVPSNNC3IXERIGZCB4.jpg)