Composite Envisions Infusion Epoxy Medium Cure Kit - Composite Envisions

Our CE Infusion Epoxy is the next generation of our house brand epoxy system that has been custom formulated for use in resin infusion and VARTM processes. This Medium Cure Infusion Epoxy system was formulated to provide for rapid saturation of carbon fiber laminate, fiberglass and Kevlar, while also allowing for maximum open time. Processability parameters

Our CE Infusion Epoxy is the next generation of our house brand epoxy system that has been custom formulated for use in resin infusion and VARTM processes. This Medium Cure Infusion Epoxy system was formulated to provide for rapid saturation of carbon fiber laminate, fiberglass and Kevlar, while also allowing for maximum open time. Processability parameters are enhanced due to the infusion epoxies low mixed viscosity and wet-out potential. This system is not designed for use in open mold applications. Improving on an already great formula this infusion epoxy has added benefits such as extensive testing and enhanced physical properties. One notable property is the increased Heat Deflection Temperature with our Medium hardener system reaching 195° F with an initial room temp cure and proper post cure.

A list of all notable features of this resin system are below.

High TG (up to 195° F with Medium hardener & proper post cure)

Ultra Clear System

Enhanced Degassing Properties

Low Viscosity

No hazmat fees on small kits.

Adjustable Speed – Can blend slow, medium and fast hardeners to create a speed that fits your process.

Extensive material testing with enhanced data sheets

This is very user friendly system which will provide the results needed to produce high end composite parts that not only look good, but have the structural properties to back it. This epoxy is made here in the USA. Hardener is included with this resin and each part is available separately. This system was formulated and small kits are packaged in a manner that now avoids the expensive HAZMAT fees the carriers charge.

Handling Properties

RESIN VISCOSITY, cP

1,044

ASTM D 2196

RESIN DENSITY, lb./gal

9.49

ASTM D 792

HARDENER VISCOSITY, cP

39

ASTM D 2196

HARDENER DENSITY, lb./gal

7.78

ASTM D 792

COLOR

Clear

DENSITY, lb./gal

9.02

ASTM D 792

MIX RATIO, pbv (pbw)

3/1 (3.65/1)

MIXED VISCOSITY, cP

291

ASTM D 2196

GEL TIME (200g), min

160

ASTM D 2471

WORKING TIME*, min

120

*The working time varies according to the temperature of the air, the epoxy and the surface to which it is applied.

*The working time varies according to the temperature of the air, the epoxy and the surface to which it is applied.

Note: Above viscosities/densities measured @ 77°F.

Physical Properties:

TENSILE STRENGTH, psi

10,300

ASTM D 638

TENSILE MODULUS, psi

294,000

ASTM D 638

ELONGATION @ BREAK, %

3.16

ASTM D 638

COMPRESSIVE STRENGTH, psi

13,700

ASTM D 695

COMPRESSIVE MODULUS, psi

263,000

ASTM D 695

FLEXURAL STRENGTH, psi

17,300

ASTM D 790

FLEXURAL MODULUS, psi

1,063,000

ASTM D 790

HARDNESS, Shore D

88D

ASTM D 2240

Cure Cycle: 24 hours @ Room Temperature + 8 hours @ 180°F. Test specimens for above were neat epoxy (without fiber reinforcement).

The storage temperature of Medium Infusion Epoxy will greatly affect the ease of mixing, application and curing time. For best results, Medium Infusion Epoxy should be stored at (60-80 °F or 16-27 °C) for at least 24 hours before use. Mix RESIN WITH (hardener) for 3 minutes using a Jiffy Mixer and a slow speed drill. Mix at slow speed (less than 500 rpm) to avoid air entrapment. When adding part B to part A, be sure to scrape the sides of the hardener (part B) container in order to remove all of the hardener. This is essential to maintain proper mix ratio. DO NOT mix more material than can be used within the stated working time. REMEMBER - you will have less working time at higher temperatures

SAFETY PRECAUTIONS

Avoid breathing of vapors. Forced local exhaust is recommended to effectively minimize exposure. NIOSH approved, organic vapor respirators and forced exhaust are recommended in confined areas, or when conditions (such as heated polymers, sanding) may cause high vapor concentrations. DO NOT WELD ON, BURN OR TORCH ON OR NEAR, ANY EPOXY MATERIAL. HAZARDOUS VAPOR IS RELEASED WHEN AN EPOXY IS BURNED.

Carbon Fiber Doors - DIY - Part 4 (Ep. 66)

Magnet Assisted Composite Manufacturing: A Flexible New Technique

4:1 Epoxy Hardener – Fast Cure - Composite Envisions

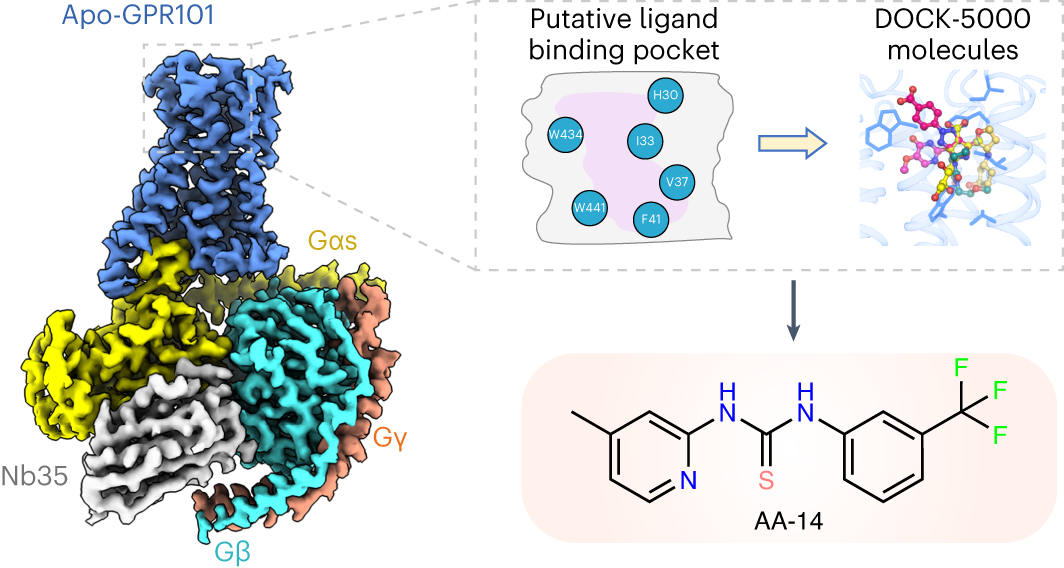

Structure of GPR101–Gs enables identification of ligands with

4:1 Epoxy Hardener – Fast Cure - Composite Envisions

Enhanced Viscosity Control in Thermosets Derived from Epoxy and

Tooling Polyester Resin Isophthalic 1 Gallon with Hardener MEKP

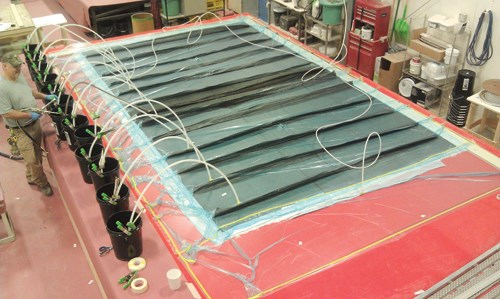

The evolution of infusion

Surface-Functionalized Cellulose Nanocrystals as Nanofillers for

Composite Envisions - Offering The Largest Selection of Carbon

Vaccum Bagging & Infusion - Composite Envisions

PRO-SET TLG-625-R Low Density Epoxy Tooling Putty Resin 4.5 Gallon

The first step in creating a carbon fiber panel is infusing the

Structural pseudocapacitors with reinforced interfaces to increase

Electrically Conductive Kevlar Fibers and Polymer-Matrix

/product/49/2359652/1.jpg?1257)