Why Should Calcium Carbonate be Surface Coated?

Surface modification is an important way to improve the performance of calcium carbonate, improve its applicability, and expand the market.

pakistan Lahore coated calcium carbonate Wsd chemical

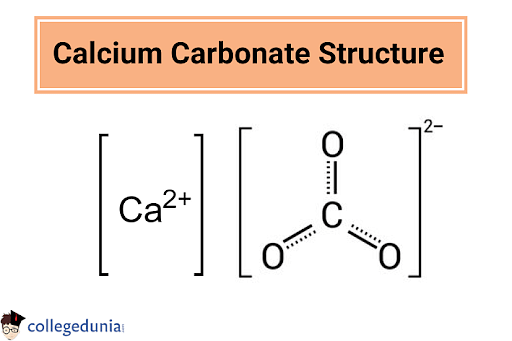

Study on surface modification of ground calcium carbonate with novel modifier and its PVC filling performance - ScienceDirect

Application of stearic acid in surface modification of nanometer calcium carbonate - ALPA Powder Equipment

More Product and Industry Information

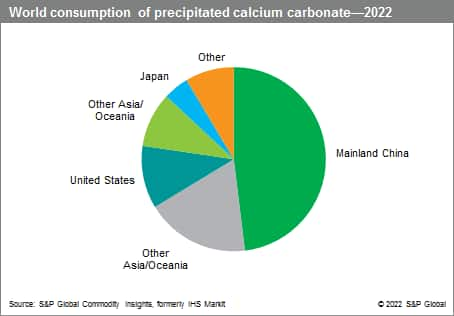

Calcium Carbonate, Fine-Ground and Precipitated - Chemical Economics Handbook (CEH)

Почему следует покрывать карбонат кальция?

EPIC_Process】 Why surface #coating #modification on ground #calcium carbonate?

Effect of Polymer Nano- and Microparticles on Calcium Carbonate Crystallization

Synthesis of calcium carbonate nanoparticles in erythrocytes enables efficient removal of extracellular lead ions

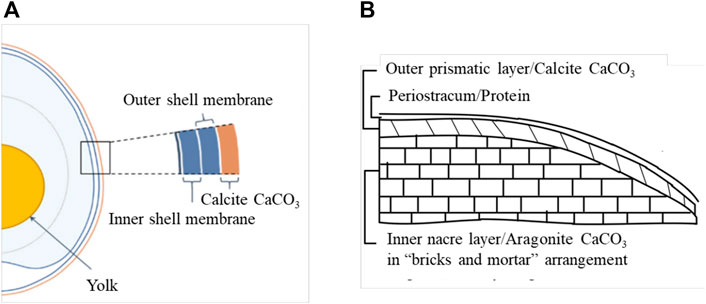

Frontiers Biogenic calcium carbonate derived from waste shells for advanced material applications: A review

PDF] SURFACE-COATED CALCIUM CARBONATE PARTICLES, METHOD FOR MANUFACTURING SAME, AND ADHESIVE BACKGROUND OF THE INVENTION

EP0323697A1 - Process for preparing finely divided calcium carbonate and its use as a filler in polymeric compositions - Google Patents

Why Should Calcium Carbonate be Surface Coated?

More Product and Industry Information